Article Quick Links

Article Quick Links

Optimizing Your Landscaping Fleet: Why Landscapers Are Switching from Trailers to Cargo Vans with Ramps

For decades, landscaping fleets have relied on the same setup: a pickup truck and a landscaping trailer loaded with mowers, blowers, and trimmers. But across the country, forward-thinking landscape business owners are rethinking that model — and replacing their trailers with cargo vans equipped with ramps.

The reason? Better fuel economy, faster job-site turnaround, and safer, more organized operations.

In this guide, we’ll break down why so many landscaping companies are upgrading to cargo vans with ramps, how the switch improves efficiency and safety, and which van ramp systems — including HandiRamp’s industry-leading cargo van ramps — make the biggest difference for your bottom line.

See how HandiRamp’s cargo van ramps are helping landscapers upgrade their fleets

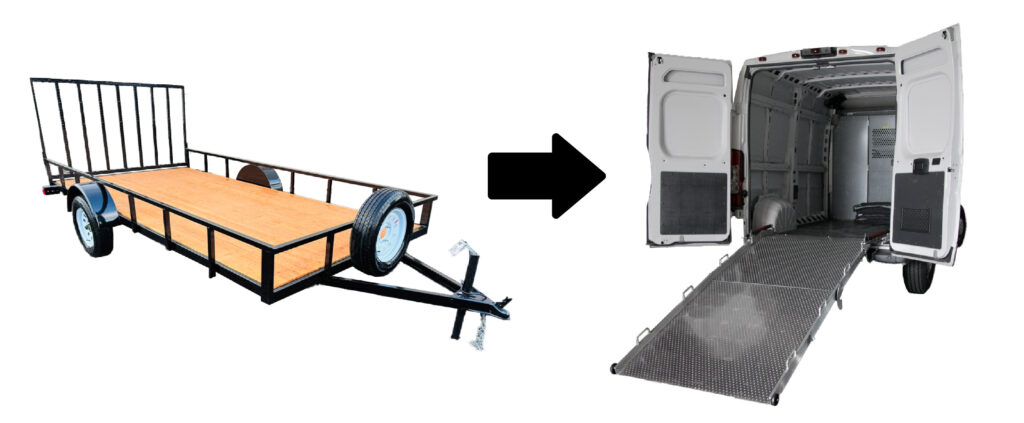

The Shift from Trailers to Cargo Vans

Landscaping is a business of margins: every gallon of gas, every minute of downtime, and every strained back counts.

A truck-and-trailer setup has long been the default, but trailers come with challenges that eat into profits:

- Higher maintenance costs — more tires, brakes, and registration fees

- Parking and maneuvering headaches — especially in tight residential neighborhoods

- Greater fuel consumption — towing can cut fuel economy by 20–30%

- Safety risks — more accidents and manual lifting injuries.

By contrast, a landscaping van offers a self-contained, secure workspace with built-in storage, tool organization, and—when paired with a cargo van ramp—streamlined loading and unloading.

Fleet managers have noticed. Over the past five years, industry data shows a growing migration from landscaping trailers to vans like the Ford Transit, Ram ProMaster, and Mercedes Sprinter. These models now dominate the light-commercial fleet sector for service trades, including landscaping, plumbing, and maintenance.

The ROI of Cargo Vans with Ramps

Switching from trailers to vans isn’t just about convenience — it’s about measurable return on investment.

Let’s look at the core benefits that drive landscapers to make the change.

🔧 1. Reduced Operating and Maintenance Costs

A typical tandem-axle landscaping trailer requires new tires every 10,000–15,000 miles, regular bearing, brake and wiring work. Annual maintenance can easily exceed $1,000 per trailer. Meanwhile, a cargo van fleet reduces those costs dramatically. One vehicle means fewer tires, fewer registrations, and no trailer hitches, lights, or bearings to maintain. Plus, towing increases fuel consumption — a 2022 AAA fleet study found trucks towing trailers use 20–25% more fuel than cargo vans carrying equivalent loads. Over a season, that’s thousands in savings.

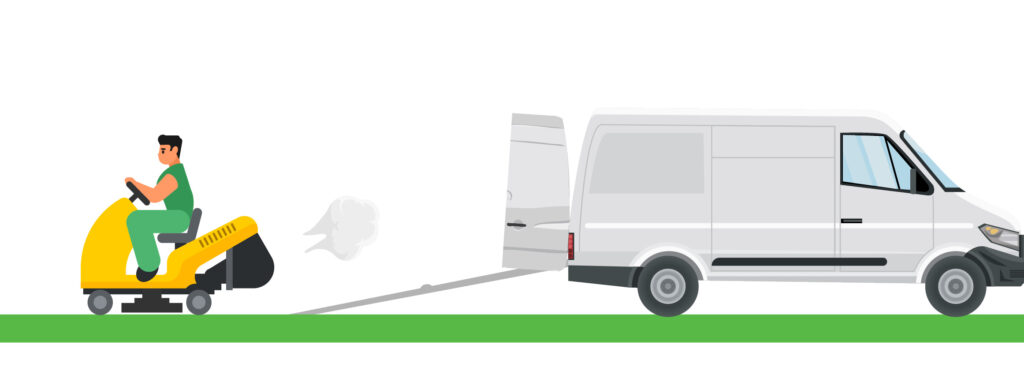

⏱️ 2. Faster Load/Unload Times

Every minute counts when crews move from job to job. Traditional setups require detaching straps, rolling mowers up ramps, and securing everything again. With a folding ramp for cargo vans, the process is streamlined: Simply fold down the ramp, roll in your equipment, secure it, and go. No hitching, no trailer jack, no wasted time backing into small driveways. For a two-crew operation completing 6–8 jobs a day, saving even 10 minutes per job adds up to almost an hour per day—that’s 250 hours a year of reclaimed productivity.

🛡️ 3. Safety and Ergonomics

Landscaping is physically demanding. Constantly lifting heavy equipment or maneuvering it up steep trailer ramps leads to back, shoulder, and knee injuries. A properly designed cargo van ramp—such as HandiRamp’s lightweight aluminum models—reduces strain through: • Lower ramp angles for easier pushing and pulling • Slip-resistant traction surfaces even when wet • Wider loading zones that fit zero-turn mowers or carts According to the U.S. Bureau of Labor Statistics, sprain and strain injuries account for nearly 35% of all landscaping-related incidents. Upgrading to an ergonomic ramp system is one of the easiest ways to improve employee safety and retention.

🚐 4. Professional Image and Security

Landscapers know first impressions matter. A clean, branded landscaping van projects professionalism, especially for high-end residential or municipal clients. Equipment stored inside a van is also protected from theft and weather, unlike trailers left outside overnight. With organized shelving and lighting, your crew can work efficiently even before sunrise.

Boost Your ROI Today

Choosing the Right Cargo Van Ramp for Landscaping Use

HandiRamp manufactures cargo ramps for vans that fit virtually every commercial model—including Ford Transit, Ram ProMaster, Mercedes Sprinter, and Transit Connect.

Here’s what to look for when selecting the ideal ramp for your landscaping fleet:

1. Ramp Type: Folding vs. Portable

- Folding cargo van ramps bolt directly to the van’s floor and fold vertically for storage. Ideal for daily commercial use.

- Portable aluminum ramps offer flexibility—use them across multiple vans or at worksites with curbs or elevation changes.

2. Ramp Length and Angle

The correct ramp length ensures safe loading. The goal is to maintain a slope ratio around 1:4 (14–15°) for powered equipment.

Load Height (van floor) | Minimum Ramp Length | Recommended Ramp Length |

28 in (Transit High Roof) | 9 ft | 10.5 ft |

21 in (ProMaster) | 7.5 ft | 10.5 ft |

28 in (Sprinter High Roof) | 9 ft | 10.5 ft |

3. Ramp Width and Capacity

Landscaping mowers and carts can weigh anywhere from 400 to 1,200 lbs. HandiRamp’s heavy-duty aluminum van ramps are rated up to 1,500 lbs, accommodating walk-behind and stand-on mowers with ease. The minimum width, if it accommodates your equipment, would be 45”, but most of our landscaping and lawn care companies opt for the 52” wide ramps.

4. Weight and Material

Aluminum offers the best balance of strength and portability. Compared to steel, it’s rust-proof and about 30% lighter, making it easier to deploy multiple times per day.

5. Compatibility

Before purchasing, verify rear-door dimensions:

- Ford Transit High Roof: 74″ door height (tapers slightly at top)

- Ram ProMaster High Roof: 70″ door height

- Mercedes Sprinter High Roof: 72″ door height

Our Cargo Van Ramp Configurator helps you confirm dimensions and choose the perfect ramp fit for your van model and business needs.

Use our Cargo Van Ramp Configurator to confirm the perfect fit for your vehicle.

The Economics: Van vs. Trailer for Landscapers

Category

Truck + Trailer Setup

Cargo Van with Ramp

Fuel Efficiency

10-12 MPG (Loaded)

15-18 MPG

Maintenance Costs

Higher (two registrations, more tires/brakes)

Lower (single vehicle)

Load Time per Job

15 min avg

5 min avg

Equipment Security

Exposed

Enclosed and Lockable

Image/Branding

Standard

Professional & cohesive

Ramp Storage

External

Build-in Folding

Roi

Moderate

High (time + fuel + labor savings)

Over a three-year period, switching to cargo vans with ramps can reduce total fleet costs by 15–25%, according to internal HandiRamp customer data.

Safety and Compliance: OSHA Considerations

OSHA requires employers to minimize manual lifting and provide ergonomic tools whenever possible. Installing a ramp for cargo vans directly supports these standards by:

- Reducing lifting forces below the 50 lb limit

- Providing stable footing with high-traction surfaces

- Lowering risk of slips and falls when loading in wet or uneven conditions

HandiRamp’s aluminum cargo van ramps exceed OSHA safety recommendations for slope, traction, and load rating.

FAQ

Final Thoughts: The Smart Upgrade for Modern Landscapers

The landscaping industry is evolving, and your fleet should too. Transitioning from traditional landscaping trailers to cargo vans with ramps can streamline operations, lower expenses, and keep your crew safe.

At HandiRamp, we’ve helped hundreds of contractors and fleet managers modernize their operations with our durable aluminum cargo van ramps — designed, manufactured, and supported in the USA.

Whether you manage a single van or an entire fleet, our experts can help you choose the right ramp for Ford Transit, ProMaster, or Sprinter van to match your equipment and workload.

Transform your landscaping business with HandiRamp’s cargo van ramps — built for pros, made in the USA.